Working Principle Of Resistive And Capacitive Touchscreen - Monitor supported by touch screen technology (touchscreen) have become a common part of various electronic devices that we use everyday such as smartphones, tablets, laptops, Smart TV and others. You must have felt the difference when using the touch screen on different devices. This is because there are several types of touch screen technology is common on the market.

|

| Working Principle Of Resistive And Capacitive Touchscreen |

Basically, there are three basic systems that are already commonly used by manufacturers of electronic devices to recognize touch. Each kind uses different ways of working:

- resistive

- capacitive

- Surface acoustic wave

Here's an explanation of each advantages and disadvantages of the touch screen above.

|

| resistive touch screen working principle | | | | |

Resistive touch screen system consists of a normal glass panel that is covered by a conductive material and a resistive metallic layer. Both layers are separated by a certain distance, and a scratch-resistant coating that is placed at the very top. An electrical current runs through the two layers while the monitor is on. When the user touches the screen, the two layers make contact stretcher just a touch going on. Electrical changes noted and the coordinates of the point of contact is calculated by the processor. Once the coordinates are known, a special driver translates the touch into electrical signals understood by the operating system. It is just like the workings of a computer mouse driver translates a mouse movement, click and drag. In the resistive system, we have to press the screen so that contact occurs between the two layers.

|

| Capative touch screen working principle | | |

In the capacitive system, a layer that stores electrical charge is placed on the glass panel of the monitor. When

the user touches the monitor with or finger, a number of electric

charge is transferred to the user, so the charge on the capacitive layer

decreases. This decrease is measured in circuits located at each corner of the monitor. The

processor calculates from the relative differences that occur in every

corner of the resulting value exactly where the touch and then send that

information touchscreen driver software. One

of the advantages of capacitive system than the resistive system is

capable of sending nearly 90 percent of the light from the monitor,

whereas the resistive system only transmits about 75 percent. So that the capacitive system could provide a clearer picture than the resistive system. We just need to touch the surface, without the need to press for the electrical charge is able to walk with a touch. This system is widely used for smartphones and tablets today.

|

| surface acoustic wave |

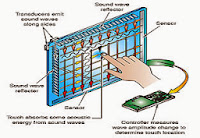

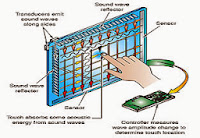

Furthermore,

the monitor that utilizes technology acoustic wave system, two

transducers (one recipient and the sender) placed along the x and y axes

of the monitor's glass plate. It also placed a reflector to reflect an electrical signal sent from one transducer to the other transducer. Transducer receiver can determine whether a wave had been exposed to touch all the time, and can find a suitable location. The

movement of this wave requires no metallic layers on the screen,

allowing it to display the throughput and perfect image clarity of 100

percent. This makes the surface acoustic wave system is the best choice for

displaying graphics with high detail than resistive or capacitive

systems.

Another difference between the systems at the top is where the stimulus would be considered a touch. Resistive

system will process all the touches that can make the two layers make

contact, whether you touch with your hands or with other objects that

are insulators. While

the capacitive system, on the other hand must have a conductive input,

in general is your finger, to create a stimulus that is able to be

processed by the system and the system will not run if your fingers are

covered with a layer which does not conduct electricity like a glove. On the surface acoustic wave system works like the resistive system,

which allows it to work with a touch almost of all objects, except hard

and small objects like a pen tip.

From

the price, the resistive system is the cheapest but the monitor

kejernikan lowest level, as well as layers that are easily damaged by

sharp objects. While surface

Related Posts: